Electron Microbeam & X-Ray Diffraction Facility (EMXDF)

An integration of three laboratories comprising a JEOL JXA-iHP200F field emission electron microprobe analyzer (EPMA), Hitachi SU3900 scanning electron microscope (SEM), Bruker D8 Endeavor and D8 Advance X-ray powder diffractometers (XRD).

The Electron Microbeam/X-ray Diffraction Facility is an integration of three laboratories comprising a JEOL JXA-iHP200F field emission electron microprobe analyzer (EPMA), Hitachi SU3900 scanning electron microscope (SEM), Bruker D8 Endeavor and D8 Advance X-ray powder diffractometers (XRD). Two preparation laboratories with a carbon evaporator unit, micronizing mill, spray dryer, and other equipment support these operations.

The electron microprobe, scanning electron microscope and associated preparation laboratory are housed in a specially-built low-vibration ground-floor laboratory complex with air conditioning and clean-air system; the X-ray powder diffractometers and its preparation laboratory are housed elsewhere in the building. These three laboratories have been merged into a modern analytical facility for the comprehensive characterization of minerals and materials. The labs are supported by full-time Research Scientists Dr. Anette von der Handt, Dr. Cole Mauws, Jenny Lai, and Lan Kato.

Clients of the facility include researchers from within the department and other departments at the University of British Columbia, University of Victoria, Simon Fraser University, Western Washington University; federal and provincial governments; and other academic institutions, both local and international. We provide comprehensive training for graduate and undergraduate students, postdoctoral fellows, and faculty, equipping them not only with how to operate the instruments but also to understand all aspects of this analytical methodology, including strategic analysis, data acquisition, data reduction, and result interpretation. A class on these analytical techniques is offered: EOSC 521 – Microbeam and Diffraction Methods for the Characterization of Minerals and Materials.

The facility offers analytical services to the private sector. While our primary focus for XRD is on quantitative phase analysis utilizing the Rietveld method for exploration, mining, mineral processing, and environmental remediation, we also provide a variety of services (EPMA, SEM, XRD) to clients across other engineering and technical disciplines, as well as various industries within the high-technology sector.

Sample Submission

Quantitative Analysis by Powder X-Ray Diffraction (Rietveld)

Standard samples submitted for quantitative Rietveld analysis should consist of 5-10g of dry, pulped, homogeneous material with a particle size less than 420µm (40 mesh). Please inquire for small sample sizes, non-mineral samples, or other PXRD methods.

Electron Probe Microanalysis

Samples for the electron microprobe should have a highly polished “mirror” surface (at or better than 1 micron). We can accommodate thin/thick sections, or polished pucks (25mm or 32 mm). Pucks of 25mm diameter are preferred. Samples should be submitted uncoated, and a carbon coating will be applied in-house.

Scanning Electron Microscopy

Samples for the SEM should be clean and dry, and free of any oils or contaminants. Our system readily accepts small grains of material or flat sections, but can only accommodate samples up to 300mm in diameter and 5kg.

Instrumentation

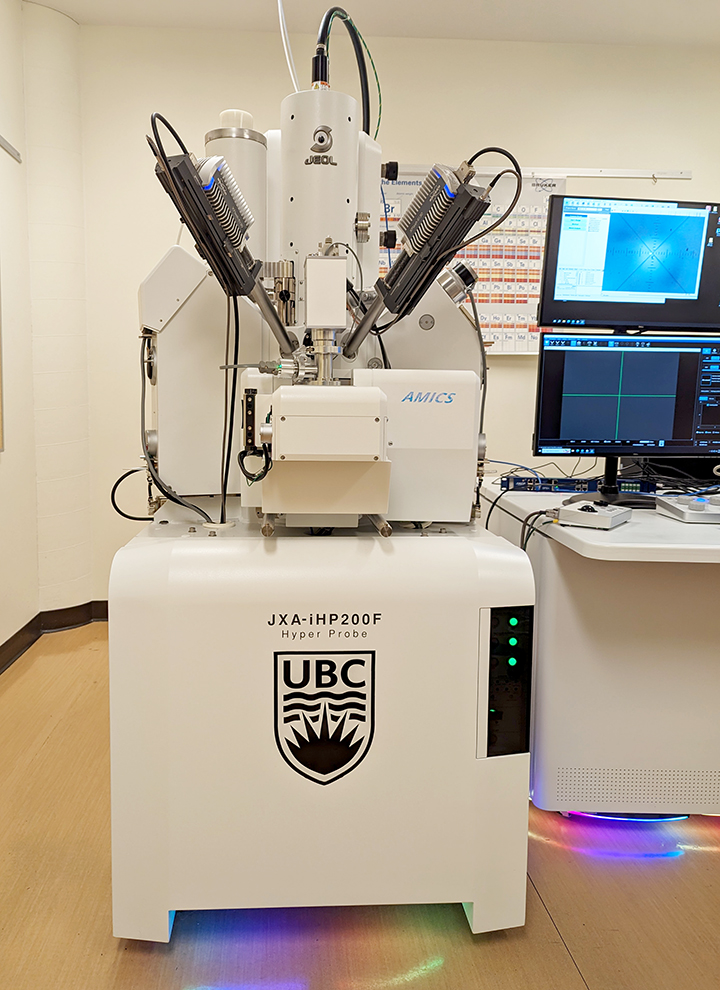

Electron microprobe

The laboratory features a state-of-the-art JEOL JXA-iHP200F field emission electron microprobe with 5 wavelength-dispersive X-ray spectrometers (WDS) and dual Bruker XFlash6 30mm2 SDD-energy dispersive X-ray spectrometers (EDS). The WDS spectrometers are equipped with standard (TAP, PETJ, LIF), large-sized (TAPL, PETL, LIFL) and specialized light element (LDE1L, LDE6L) analytical crystals. Additionally, the laboratory maintains a comprehensive standard library that encompasses nearly all elements and common alloys. For data acquisition, we utilize Probe-for-EPMA and Probe Image software (Probe Software, Inc.), which allows for integrated EDS-WDS data collection, as well as user-friendly sample navigation, documentation, and reporting capabilities. The instrument is capable of generating X-ray element maps using either EDS or WDS spectrometers, along with backscattered and secondary electron images. Automated mineralogy applications are facilitated through Bruker’s AMICS software, and remote operation is feasible in certain instances.

Scanning electron microscope

The Hitachi SU3900 SEM enables efficient examination and digital imaging of minerals and materials at both low and high magnifications, utilizing secondary electrons, backscattered electrons, characteristic X-rays, and cathodoluminescence signals. Its dual Bruker XFlash7 30mm2 SDD-energy dispersive X-ray spectrometers enable mapping at exceptionally high input count rates, thus optimizing sample throughput for automated mineralogy. Cathodoluminescence (CL) capabilities are provided by the built-in Hitachi UVD detector and a high-end DELMIC SPARC Compact detector with color-filtering capabilities. The latter supports rapid inspection of large areas using its fast PMT detector and capture of high-quality CL intensity data using the sensitive parabolic mirror collection optic. Furthermore, the SEM can operate in variable pressure mode, making it suitable for analyzing samples that cannot be coated with carbon. The instrument is specifically designed to support automated mineralogy applications through Bruker’s AMICS software and its large multipurpose specimen chamber can accommodate observation of large samples.

X-ray powder diffractometers

Our Bruker D8 Endeavor and D8 Advance diffractometers are equipped with Co-Kα sources, large sample changers (66 and 90 samples, respectively) and energy discriminating Lynxeye-XE-T detectors for Kβ and fluorescence suppression, allowing for rapid data acquisition. Diffraction data may be directly analyzed by users or processed internally. We use the Bruker EVA software for phase identification with the International Centre for Diffraction Data (ICDD) PDF-5 database and the TOPAS software for Rietveld data analysis. We have a suite of calibrated in-house standards for common clay and serpentine minerals which are difficult to quantify with conventional Rietveld analysis.

Contact

Please send inquiries to emxdf@eoas.ubc.ca